This Specialty UHMW Enhances OEM Component Longevity While Minimizing Downtime

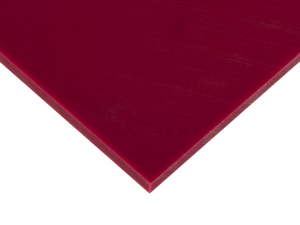

IPX 2000® UHMW from Interstate Advanced Materials is designed to meet the demands of OEM environments and prevent system failure in critical applications.

IPX 2000® is well-suited for gears, springs, and other high-wear mechanical parts due to its enhanced abrasion resistance. With up to 40% greater wear resistance than standard UHMW, it extends part life in demanding OEM environments—reducing downtime, lowering maintenance costs, and lengthening replacement cycles in high-load, repetitive-use environments.

Bushings, rollers, and sliding elements benefit from its low-friction, self-lubricating properties, which provide up to 30% more slip than nylon, acetal, or traditional UHMW. This reduces energy use, eliminates external lubrication, and limits wear in dynamic assemblies.

For machined plates, housings, and structural components, the material’s dimensional stability and low thermal expansion enable tighter tolerances and minimize misalignment under temperature fluctuations.

Equipment guides, panels, and sliding elements benefit from IPX 2000®’s UV resistance. Designed for prolonged exposure to sunlight and harsh weather, it resists discoloration, surface degradation, and mechanical wear while maintaining its appearance and function over time.

In harsh industrial environments, OEM components and processing machinery are supported by the material’s strong chemical resistance and low moisture absorption. Unlike metal, it won’t rust, swell, or corrode, ensuring long-term reliability in conditions where corrosion or deformation can compromise performance.

Interstate Advanced Materials offers IPX 2000® UHMW in full sheet and cut-to-size options. OEM professionals looking to control their material costs can save 30%+ on IPX 2000® UHMW and other materials with an Interstate Advanced Materials membership. To learn more about OEM material solutions, call a material expert today at 800-742-3444.

Interstate Advanced Materials is a full-line distributor of high-performance sheet, rod, tube, plate, and bar, and proudly serves many diverse industries, including OEM, semiconductor, food processing, POP display, government, agriculture, automotive, and many others. With 10 locations nationwide and an online sales and support team, Interstate Advanced Materials provides full sheets and pallets, cut-to-size service, complex CNC, welding solutions, and full machining capabilities.

Interstate Advanced Materials is known for selling high-quality products, providing excellent customer service, and providing superior technical support. Excellence in all facets of the customer experience has been the cornerstone of Interstate Advanced Materials for over 40 years.

Stephen Sowinski

Interstate Advanced Materials

+1 800-742-3444

stephen.s@interstateAM.com

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

What is UHMW IPX 2000®?

Distribution channels: Aviation & Aerospace Industry, Electronics Industry, Manufacturing, Mining Industry, Shipping, Storage & Logistics

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release